A seamless tube is a tube that does not have any welding seam. The seamless tube will ideally be a solid metal tube with each end connected to another tube without having any welding joint. These tubes have threads either at one end or at both ends and can be threaded to the end of another hollow tube or pipe.

The presence of any seam on a welded tube acts as a weak point, however if the tube is seamless, it tends to be solid and overcome various industrial forces and pressures while in operation.

A seamless tube can be made from any of several alloys and metals such as carbon steel, stainless steel, molybdenum or tungsten. Seamless tubes are used in those industrial applications that mandate the highest safety requirements. In order to produce a seamless tube, a solid block is penetrated by a piercing plug before the tube is drawn to its desired size.

Some of the differences between seamless tubes and welded tubes are:

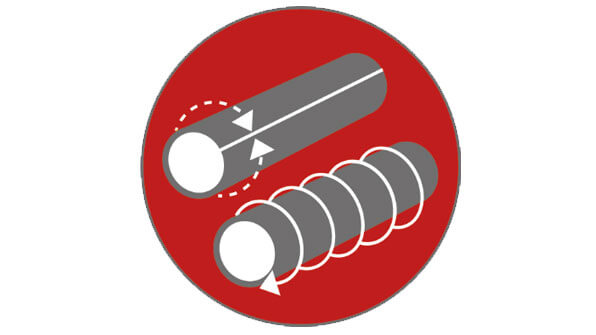

• A seamless tube is extruded and drawn from a billet whereas a welded tube is produced from a strip that is roll formed and welded to produce a tube.

• Since a seamless tube offers a higher range of safety measures it is more expensive than a welded tube.

• A seamless tube is relatively short in length, whereas welded tubes can be manufactured in long continuous lengths.

• A seamless tube generally doesn't show any sign of corrosion until and unless it is subjected to a highly corrosive environment, whereas the weld area in the welded tube is much more prone to corrosion attacks. A welded area is considered to be inhomogeneous, thus it exhibits a different malleability and less corrosion resistance as well as greater dimensional variation. A seamless tube eliminates any such issues and thus offers high corrosion resistance.