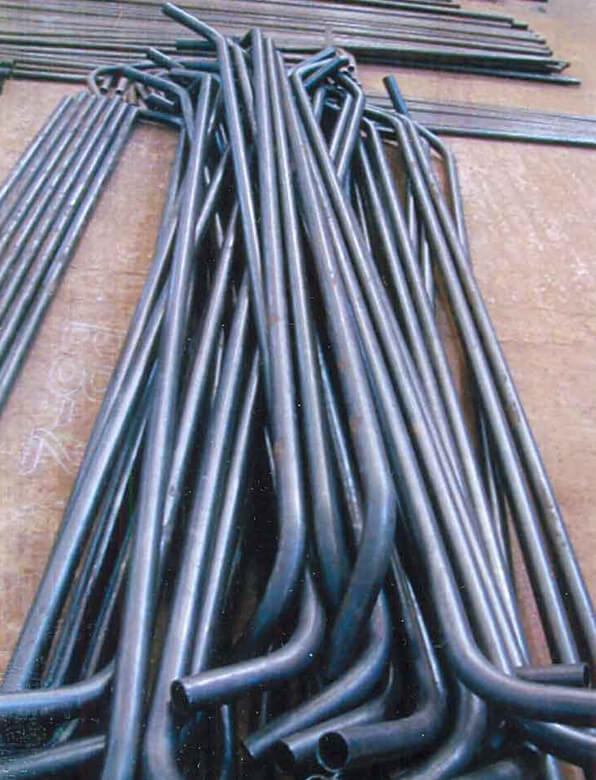

Different from cold rolling which is performed below the recrystallization temperature, hot rolling is conducted above the temperature. Hot rolled seamless pipes offer higher torsional rigidity than cold rolled ones, thus it offers better torsional resistance than cold rolled tubes.

Advantages

Hot rolled seamless steel pipe can damage the cast microstructure of the steel ingot, refinement of the crystal grains of the steel, and eliminate the defects of the microstructure, so that the the steel organization compacting, improve the mechanical properties. This improvement is reflected in the rolling direction, so that the steel is no longer to a certain extent isotropic; pouring the formation of bubbles, cracks, and osteoporosis, under high temperature and pressure can also be welded together.

Disadvantages:

• After the hot rolling, the nonmetallic inclusions in the interior of a steel (mainly sulfides and oxides, as well as the silicate) was pressed into a sheet, stratified (laminated) phenomenon appears. The layering of the steel in the thickness direction by the pull performance deteriorated significantly, and may appear in the weld shrinkage interlayer tear. Weld shrinkage induced local strain often reach several times the yield point strain, the strain is much greater than the load caused;

• Residual stress caused by uneven cooling. The residual stress is the stress of internal self-phase equilibrium in the absence of external force, the hot-rolled steel of various cross-sectional has a residual stress such Usually steel sectional dimension is the greater, the greater the residual stresses. Residual stress is self-phase equilibrium, but the steel members in the performance external force or have a certain influence. Such as deformation, stability, anti-fatigue may adversely.

• Hot-rolled steel products, poor control of thickness and edge width. We are familiar with the thermal expansion and contraction, even if the beginning of the hot-rolled out are standard length, thickness, or there will be some negative final after cooling, this negative differential edge width wider the increasing thickness of the performance of the more obvious.