Spiral Weld Pipe, as the name implies, is a steel pipe that has a seam running its entire length in a spiral form.

In the past, due to the method of manufacture, Spiral Welded pipe was relegated to low pressure and structural applications. With the development of the Submerged Arc Welding process, the production of large hot rolled coils of sufficient width and the development of dependable non-destructive testing methods, it is now possible to produce Spiral Weld pipe for high-pressure service.

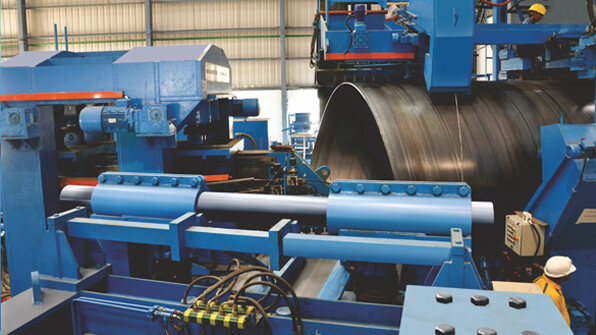

Present Spiral Weld mills consist of a de-coiling device (in the case of strip base material) or a plate preparation table (where the base material is in plate form) a strip connecting welder, straightening rollers, edge preparation tools (shearing and trimming), prebending devices, a three roller bending and cage forming system, an internal welder, an external welder (both Submerged Arc), ultrasonic testing apparatus and cutting devices.

The material passes through all these production stages continuously. The angle between the flat strip being fed into the machine and the finished pipe leaving the machine controls the pipe diameter in ratio to strip width and the angle of the weld in the pipe.

Because of the method of manufacture, a wide variety of diameters can be produced. The diameter tolerance is small, particularly with regard to ovality; and the pipe, due to its axial symmetry, has an inherent straightness. The length range is infinite and is controlled only by the economics of transportation.