Disc Thermodynamic Steam Traps

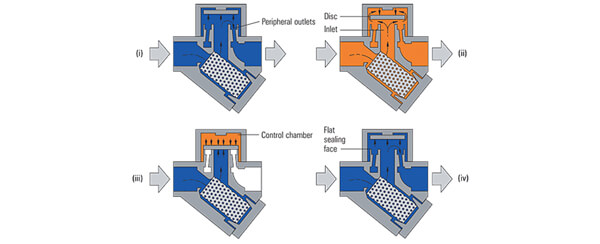

• The trap operates by means of the dynamic effect of flash steam as it passes through the trap

• On start-up, incoming pressure raises the disc, and cool condensate plus air is immediately discharged from the inner ring, under the disc

• Hot condensate flowing through the inlet passage into the chamber under the disc drops in pressure and releases flash steam moving at high velocity. This high velocity creates a low pressure area under the disc, drawing it towards its seat

• The flash steam pressure builds up inside the chamber above the disc, forcing it down against the incoming condensate until it seats on the inner and outer rings

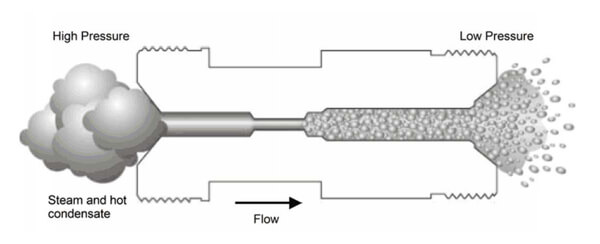

Orifice Steam Traps

• These are devices containing a hole of predetermined diameter to allow a calculated amount of condensate to flow under specific pressure conditions.

• They don’t have any moving pats.

• In case of a small orifice, the condensate flows with much lower velocity through the opening, the much denser condensate will stop the steam. The consequence of this is, no fresh steam will leak through the trap.

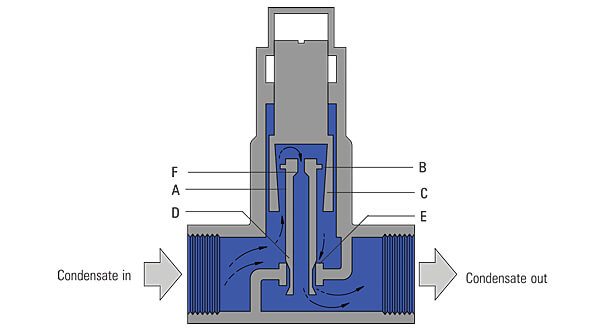

Impulse steam trap

• The impulse trap (as shown in Figure) consists of a hollow piston (A) with a piston disc (B) working inside a tapered piston (C) which acts as a guide. At 'start-up' the main valve (D) rests on the seat (E) leaving a passage of flow through the clearance between piston and cylinder and hole (F) at the top of the piston. Increasing flow of air and condensate will act on the piston disc and lift the main valve off its seat to give increased flow. Some condensate will also

• flow through the gap between the piston and disc, through E and away to the trap outlet

• As the temperature of the condensate approaches its boiling point some of it flashes to steam as it passes through the gap

• Although this is bled away through hole F it does create an intermediate pressure over the piston, which effectively positions the main valve to meet the load

• When the temperature of the condensate entering the trap drops slightly, condensate enters chamber B without flashing into steam