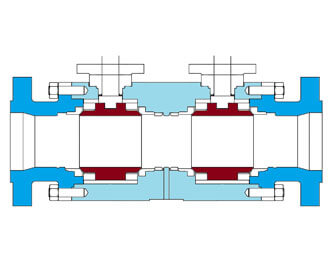

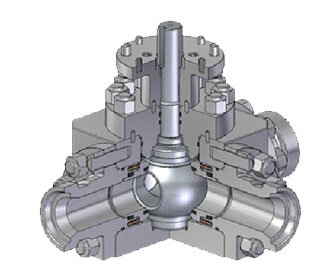

Three-way ball valve has an L- or T-shaped hole through the valve, to create multi-directional medium switch.

Moreover, multi-port ball valves such as 4 ways or more, are also available, the inlet way often being orthogonal to the plane of the outlets. For special applications, the operation is performed by rotating a single lever 4-way ball valve. The 4-way valve has two L-shaped ports in the ball that do not interconnect, sometimes referred to as an "×" port.

Features of Three Way Ball Valves:

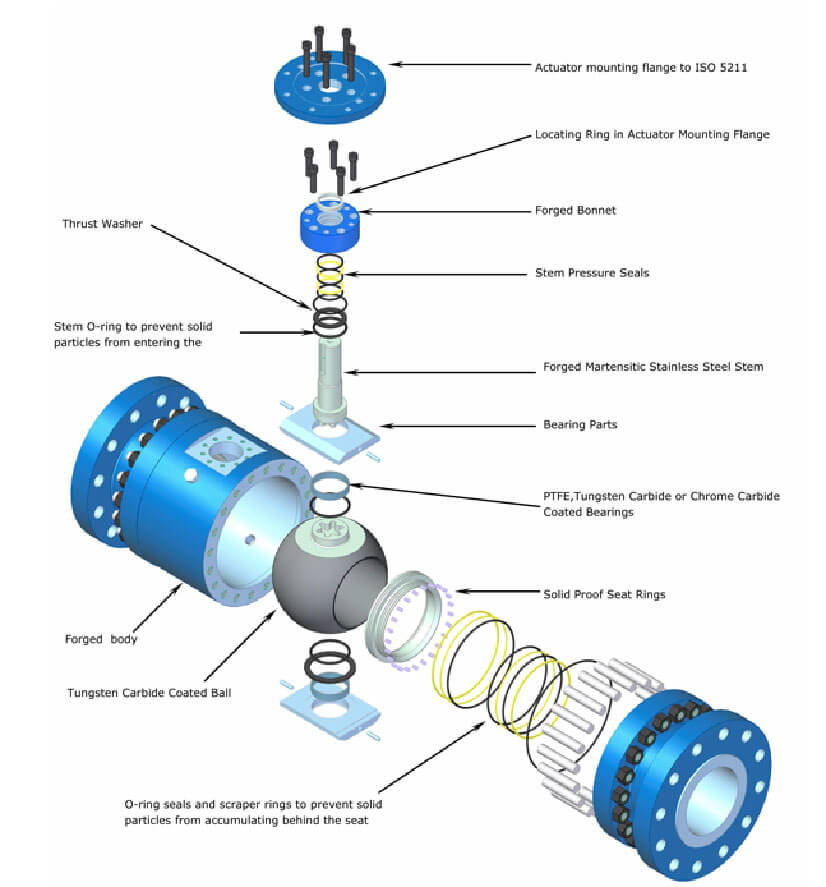

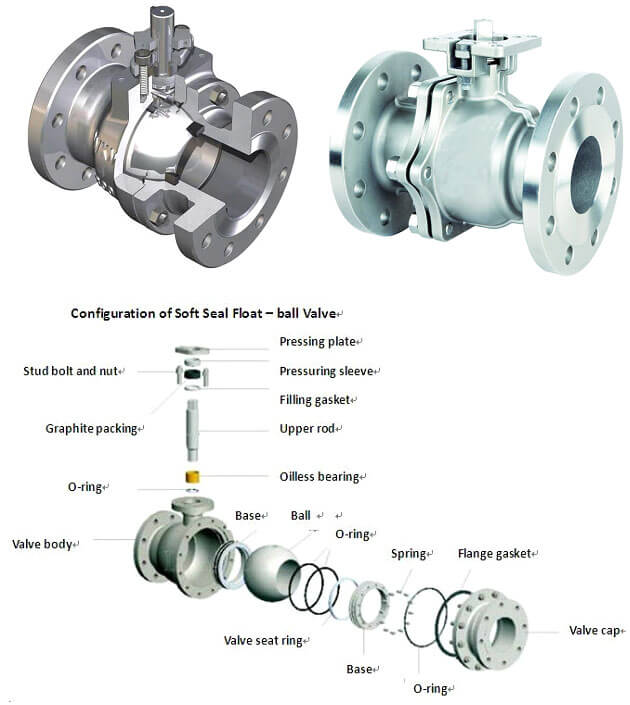

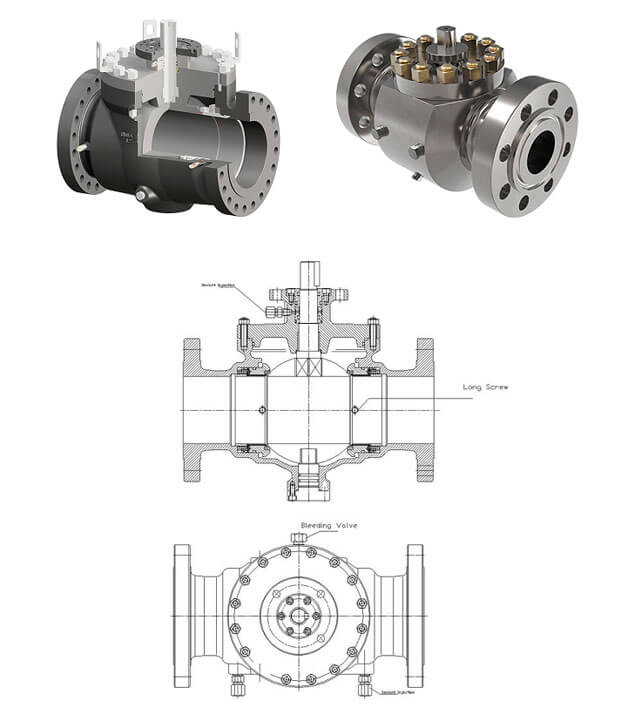

4-piece Body, Floating Ball type

L-shaped or T-shaped Ball for Various Diversion

Full Port or Reduced Port

Fire Safe to API 607

Antistatic Design

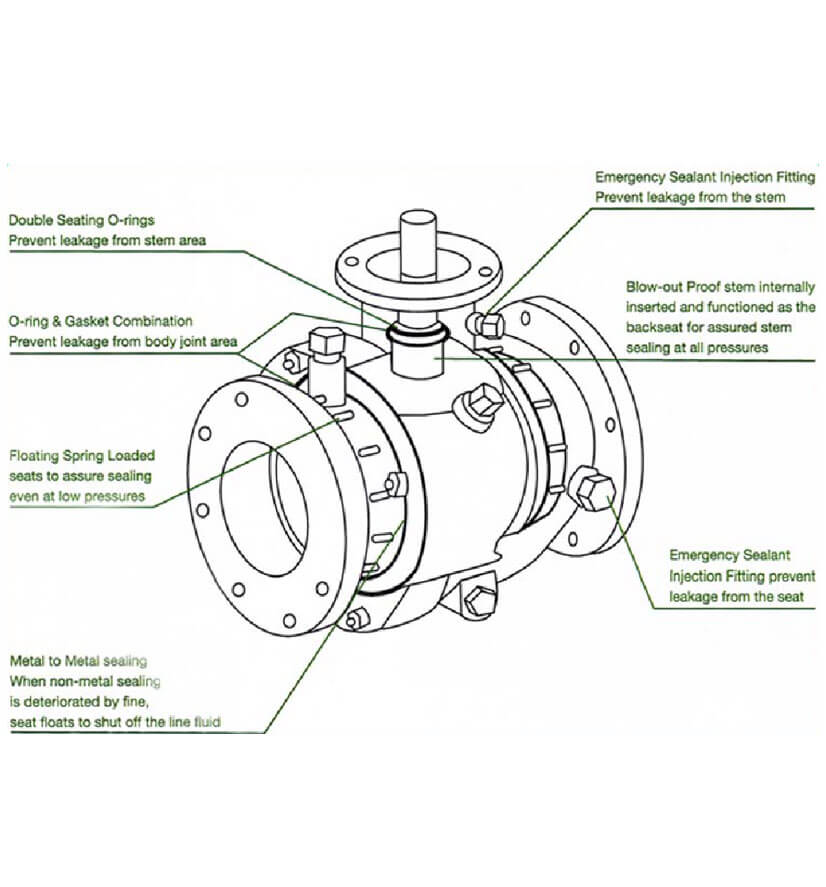

Anti-blowout Stem

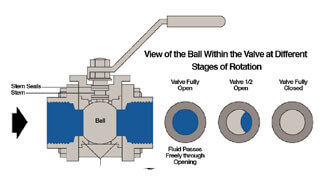

Lever, Gear Operation or Actuator Available

Applicable Standards of Three Way Ball Valves:

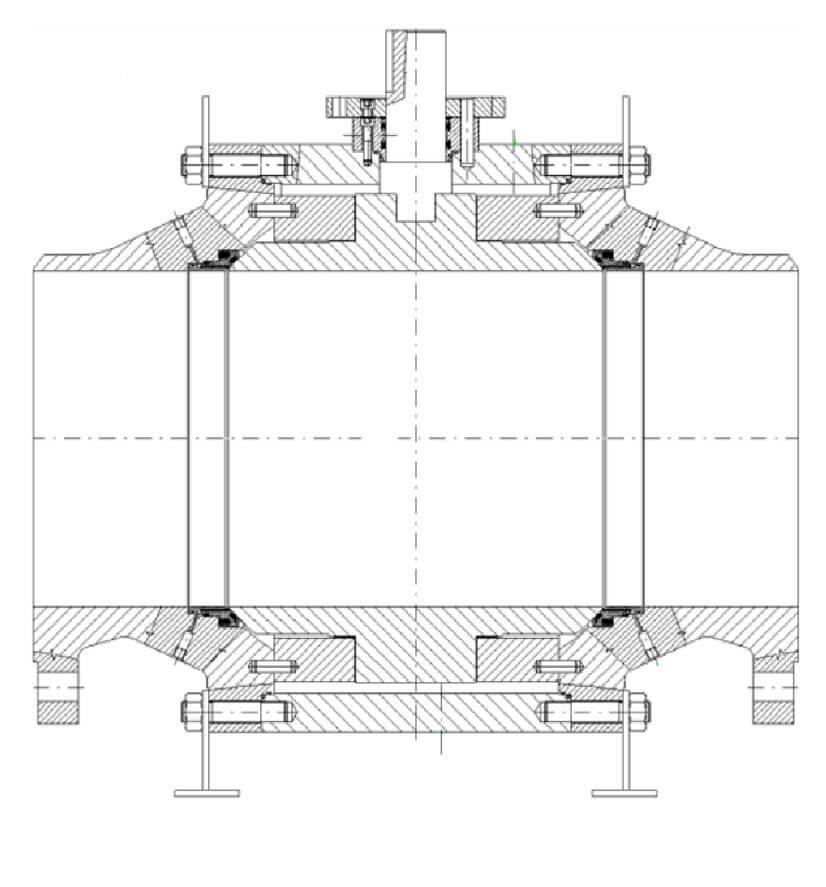

a) Design & Manufacture: API 6D, BS 5351, ASME B16.34

b) Face to Face: ASME B16.10, EN 558, API 6D

c) End Connection: ASME B16.5, EN 1092, JIS B2220

d) Test and Inspection: API 6D, EN 12266, API 598

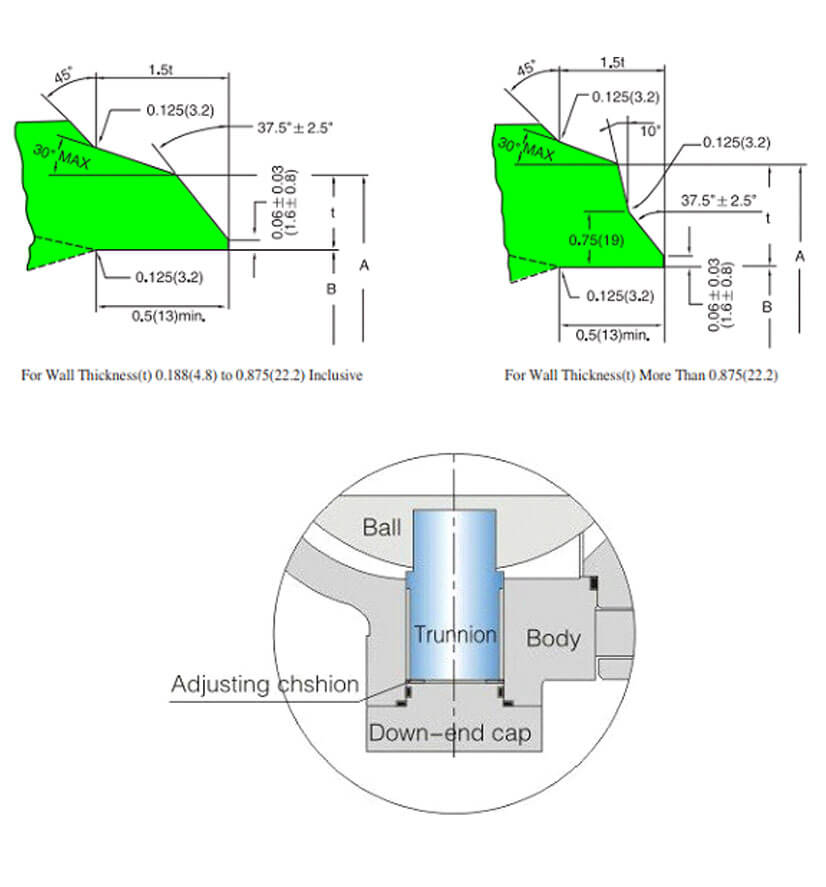

Sizes: 1/2" - 10" ,DN 15 - DN 250

Pressure Rating: Class150 - Class 600 or PN 16 - PN 100

Material of valve body: WCB, LCB, CF3, CF8M, CF3M, A105, LF2, F304, F304L, F316, F316L etc.

Operated by: Lever, Gear, Pneumatic, hydraulic and Electric actuator