• It is used to connect two lengths of pipe, and Half-coupling is screwed onto the pipe, while the other end is made to be tightly inserted, or welded, onto the other end to pipe or vessel.

• Standard Couplings have female threads or open sockets at both ends, whereas reducing couplings connect smaller pipes to larger ones.

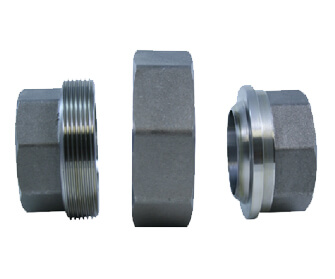

• There are three types of coupling available;

1- Full Coupling

Full Coupling is used for connecting small bore pipes. It used to connect pipe to pipe or pipe to swage or nipple. It can be threaded or socket ends types.

2- Half Coupling

Half Coupling is used for small bore branching from a vessel or large pipe. It can be threaded or socket type. It has a socket or thread end on only one side.

3- Reducing Coupling

Reducing coupling is used to connect two different sizes of pipe. It is like concentric reducer that maintains a center line of the pipe but small in size.

|

Standard Specification for Forged Coupling

|

|

Dimensions

|

ASME B16.11

BS 3799

NPT threads conform to ASME B1.20.1

|

|

Size

|

1/4”-4”

|

|

Type

|

- |

|

Class

|

2000 LBS - 9000 LBS

|

|

Variation

|

Full Coupling, Half Coupling, Reducing Coupling Threaded & Socket-Weld

|

|

Test Certificate

|

MTC as per EN10204 Type 3.1 and EN10204 Type 3.2

|