General Description

The two- and three Screw pumps are used to pump oils or other lubricating liquids, non-lubricating liquids, or liquids with poor lubricating properties. The characteristics of the screw pumps are self-priming, very high efficiency, very low noise level and very well suited for use with variable speed drives (FU). The liquid is moved fully continuously, virtually without pulsations, without turbulence, crushing, or loss of lubrication.

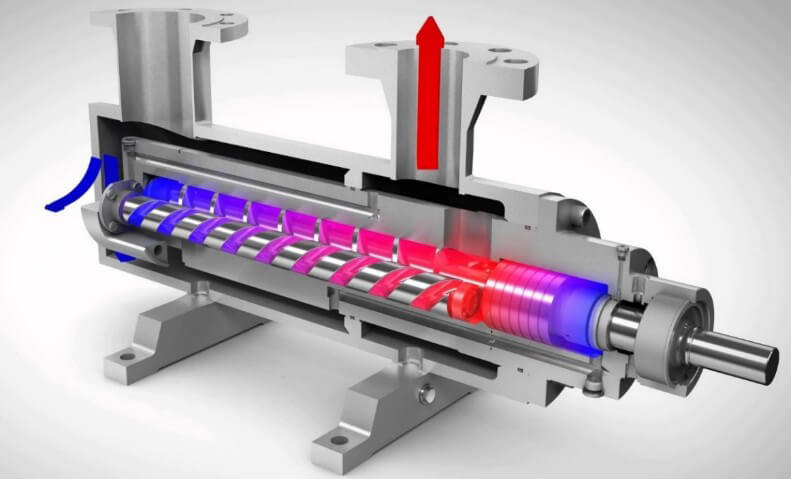

Functionality

Single- / -double channel, self-priming; the spindles have special shapes that create sealed chambers, the contents of which are continuously moved in an axial direction from the suction side to the pressure side as the spindles rotate. Despite rotation of the spindles, no turbulence results.

The uniform chamber volumes eliminate crushing forces.

Advantages

• Wide range of applications

• Self-priming

• Pumped capacity proportional to speed

• Compact construction

• Direct drive without speed-reducer possible

• Change of pumping direction - simple

• Pumping elements - simple to replace

• Easy maintenance

• For almost all media and fluids

• High viscosities possible

• Low pulsations

• Low noise level

• Dry running possible

• Constant flow on varying pressures and volumes

• Very good suction performance up to NPSH 1 - 1,5 m/3 - 5 feet

• Engineered 2-piece shaft and screw construction

Scopes of Application

• Downstream

• Marine

• Offshore

• Industry

• Food and Pharma

• Up- and Midstream