PETROSADID Company is the renowned Iranian supplier of full range of pneumatic conveying Equipment suitable for a wide range of industries such as Petrochemicals, Soaps and Detergents, Food and Pharma, Minerals and Metals, Chemicals, Cement and fly ash, Power, Foundry, Glass and Ceramics, Paints and Pigments, Inks and Resins, Rubber, Agriproduct, Ports, Paper and Newsprint and etc.

Our range will be customized as per the technical specifications provided by our clients to suit customer's need. Pneumatic Conveying is a cost- and energy-efficient method of transporting dry bulk materials such as powders and granules through an enclosed pipeline from one place to another.

The motive force for this transfer comes from a combination of pressure differential and the flow of a gas, such as air or nitrogen.

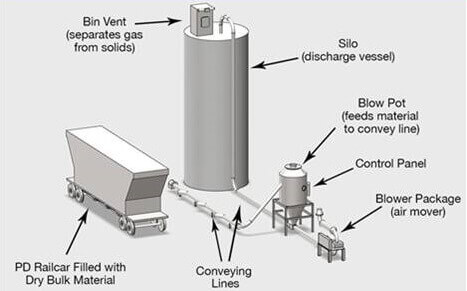

A typical example of a pneumatic conveying system that we provide and supply involves conveying material (such as polymer, lime, soda, Fly ash, plastic pellets/powder, dry milk etc.) from a railcar or truck to a silo (or vice versa).

The basic components of a pneumatic conveying system:

• An air mover (blower package)

• Conveying line from vessel containing material (header)

• Blow Pot (temporary vessel that feeds material into the line)

• Conveying line to discharge vessel (up to top of silo)

• Discharge vessel (silo)

• Filtration system to separate the solids from the gas (air) at the end of the system (bin vent)

• A control panel to control and automate functions of the system