What follows gives you a brief introduction that covers the definition and application of these feeders:

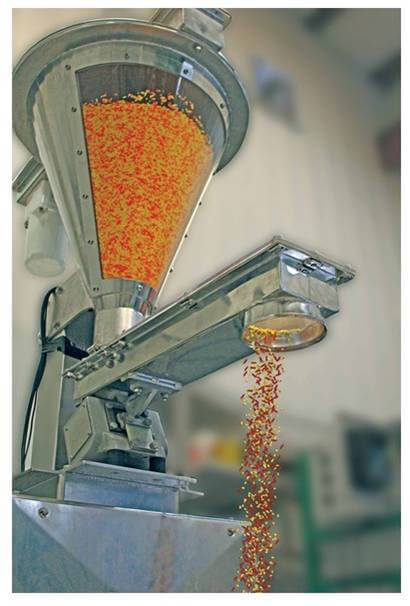

Feeders are often classified by the metering device employed to discharge material into the process. Each feeding device is engineered to handle specific types of materials and the challenges they present. Most of these material delivery methods may be configured for use in volumetric or gravimetric modes.

Your feeder selection, and the success of your application, will be greatly influenced by the specific characteristics of the materials you must feed, the recipe precision needed for your process and the throughput required.

PETROSADID Company, backed by rich industrial experiences, is able to provide you with the best solution.

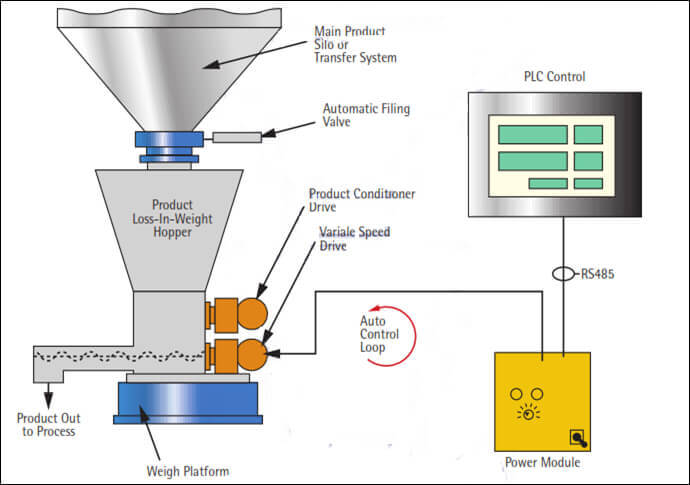

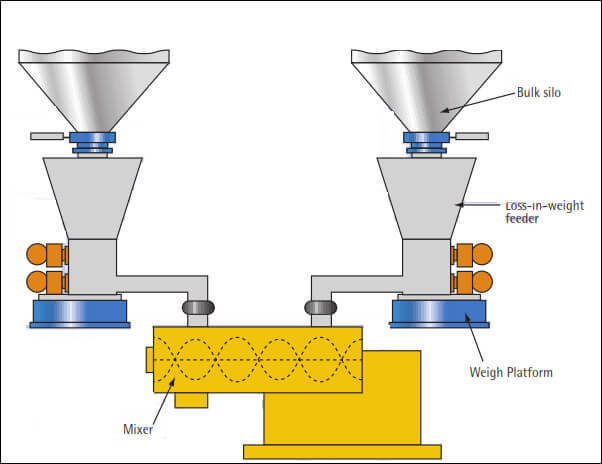

A loss in weight feeder is a gravimetric metering device that receives material from an upstream supply and accurately doses the material into a process at a pre-determined federate, typically through a screw (anger or helix), twin screw, or vibratory tray.

True to its "loss in weigh" name, this feeder's operation is regulated by the amount of live load that is lost as product is discharged. In order to do this efficiency, the loss in weight feeder receives constant feedback from a sensitive weighing device, which ensures that the precise amount of material is delivered either continuously or in each batch.