Operation

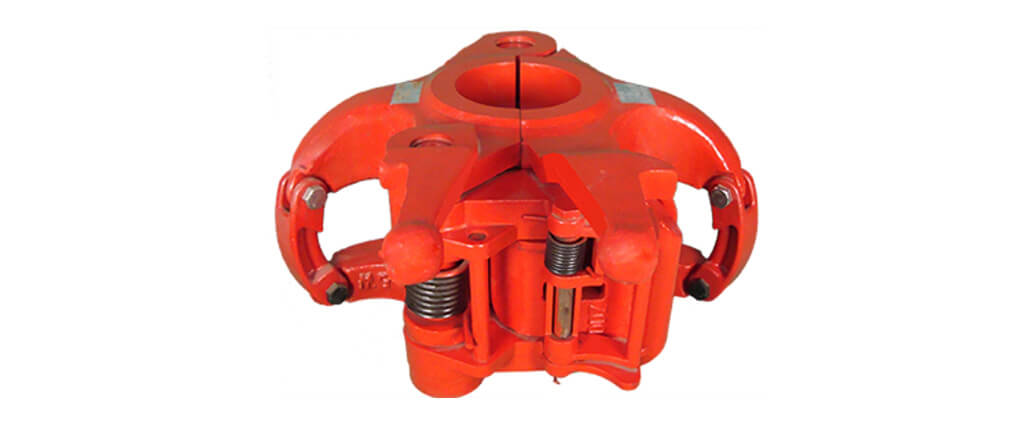

The tool is two large sets of jaws, one on top of the other, held together by a common pivot shaft and frame. The iron roughneck has to correctly center the two pipes so the threads are not cross-threaded. Some iron roughnecks have a third jaw.

The jaws are first opened to wrap the roughneck around the two sections of pipe, then clamped together to grab the pipe sections and commence the process. The lower set of jaws grabs and holds the pipe already in the well hole in place. The lower section has the female threads, and the male threaded pin end of the pipe, or tubular, screws into the lower tubular.

The turning-twisting of the upper pipe stops when the wrench’s torque reaches its preset torque limit. The two pipe sections are then locked together tightly for the last 100 degrees of rotation by the upper jaw, which can deliver much higher torque than the rotary wrench. To remove the pipes, or tubulars, the iron roughneck process is reversed, except that the upper jaw first breaks the threads apart then the rotary wrench takes over to spin the male threads all the way out of the box end, or female threads.

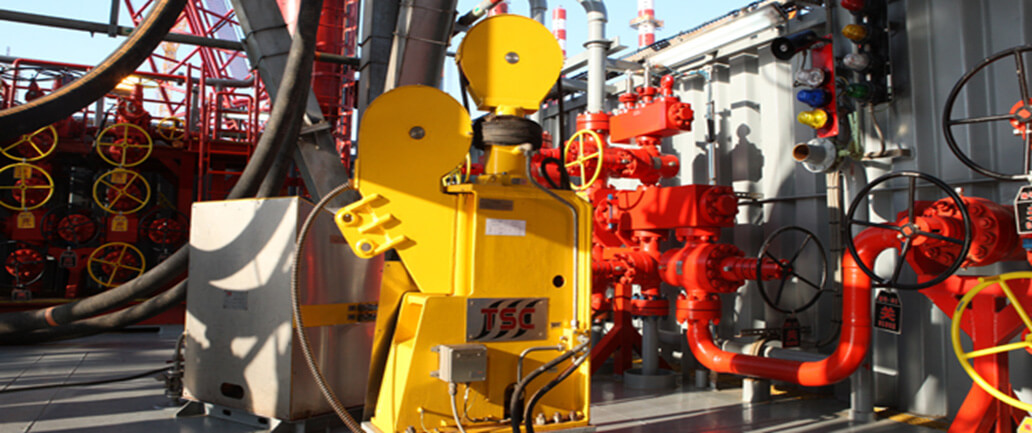

Iron roughnecks are usually hydraulically powered and controlled, but ones for remote locations can be electrically powered. Of course, remote controlled and automated iron roughnecks have to have electric power for at least the controls

Specifications

The two main specifications for iron roughnecks are the width of the pipe and the torque needed to tighten it. Almost all iron roughnecks can accommodate a wide range of both widths and torques.

Pipe Width from 2.5” to 10”

Makeup (tightening) torque up to 100K ft-lbs

Breakout (initial loosening) torque up to 120K ft-lbs

Spin torque: torque maintained while spinning the pipe at normal speed 3K ft-lb

Speed: 0 to 140 RPM

Horizontal Travel: up to 40”

Vertical Travel, or how far the pipe can be screwed in or out

Hydraulic pressure, up to 3000 psi

Stickup Height Min/Max 2.5’ to 5’

Mounts: pedestal or rail mounts

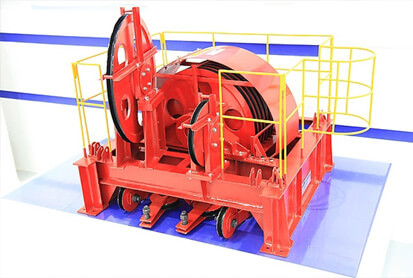

Weight of apparatus: 4 to 6 US tons

Special version for undersea drilling

Remote control options